-

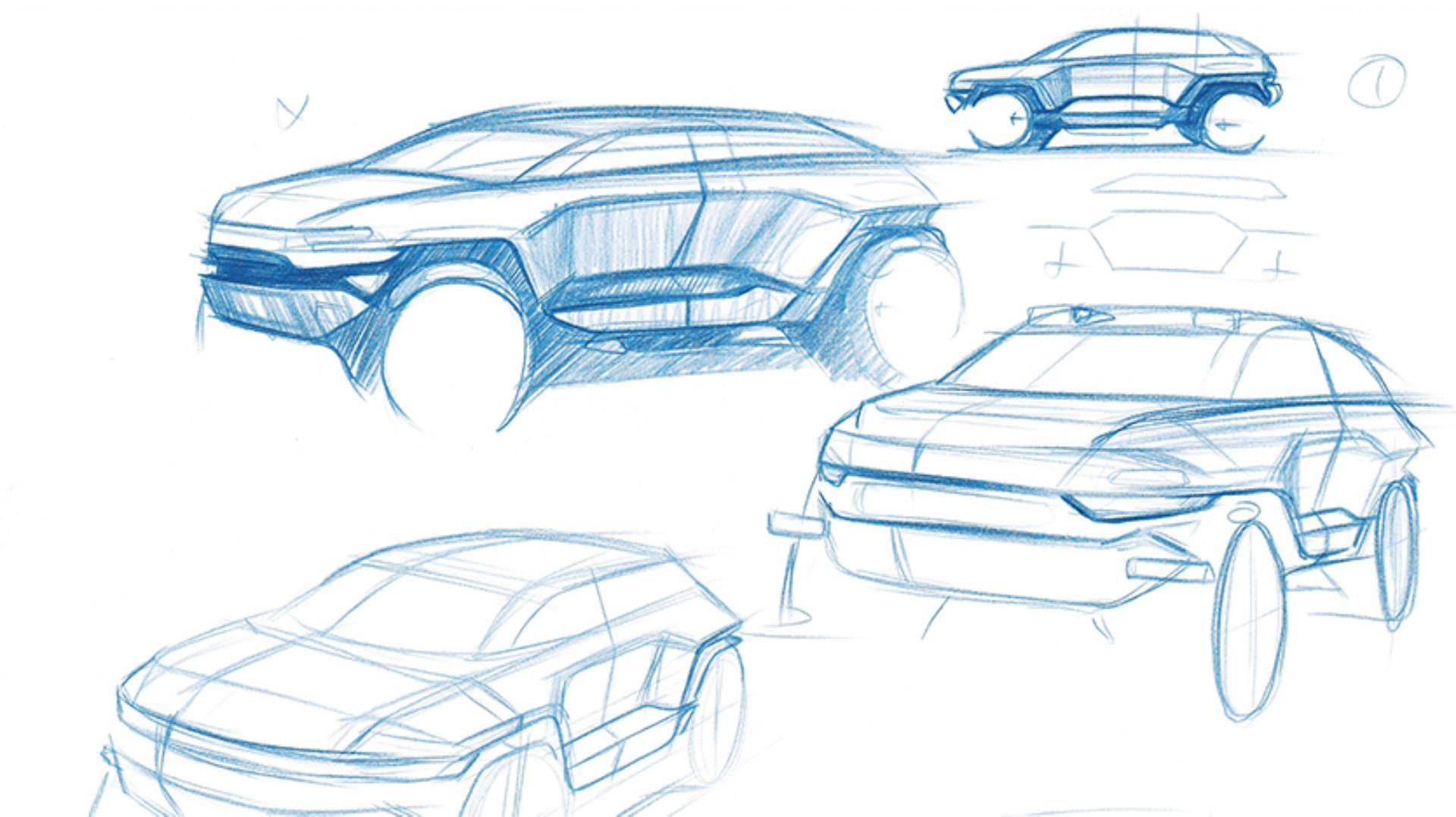

Sketch

Early concept sketches of the car.

-

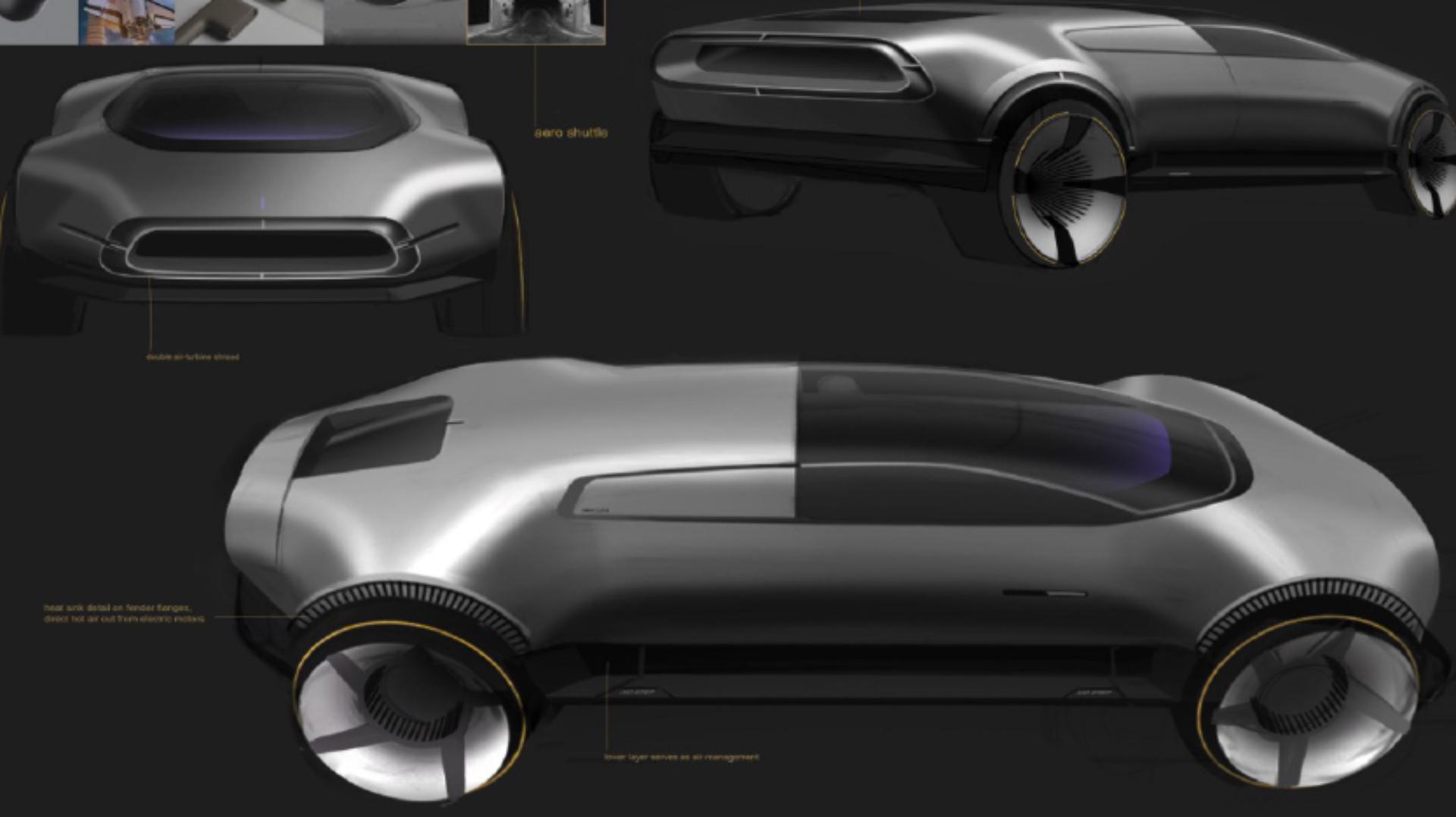

Car modelling

One of the aspects of the car project Pete and I most enjoyed was the process of working with clay on the scale model. If you look closely you can see we used a mirror to help us. The shape of the car was wholly organic, born out of the engineering rather than being specifically styled.

-

Car design

A scale model of the electric car. A top secret project for many years, N526 was our code name for it – seen here on the mocked-up registration plate.

-

Working with Pete Gammack

When we first started the car project, architect Chris Wilkinson created a secretive space for the small, exceptional team within one of our buildings on our Malmesbury campus. It happened to be next to where the production line for the vacuum cleaners once was, many years earlier. By the time I took the decision to stop the project, the team had grown to 500 and was based at our newly renovated airfield, Hullavington.

-

Car exterior

Like Alec Issigonis' design classic, the Mini, we placed the wheels of our car at the outer edges of the body. This gave greater room inside for passengers, and large battery tray and improved the handling of the car. The large wheels would have been the biggest on the market. They allowed for lower rolling resistance and an improved ride.

-

Concept

An early concept for the car.

-

Seating testing

Testing out an early version of the seats. Comfort for the driver as well as each passenger was paramount.

-

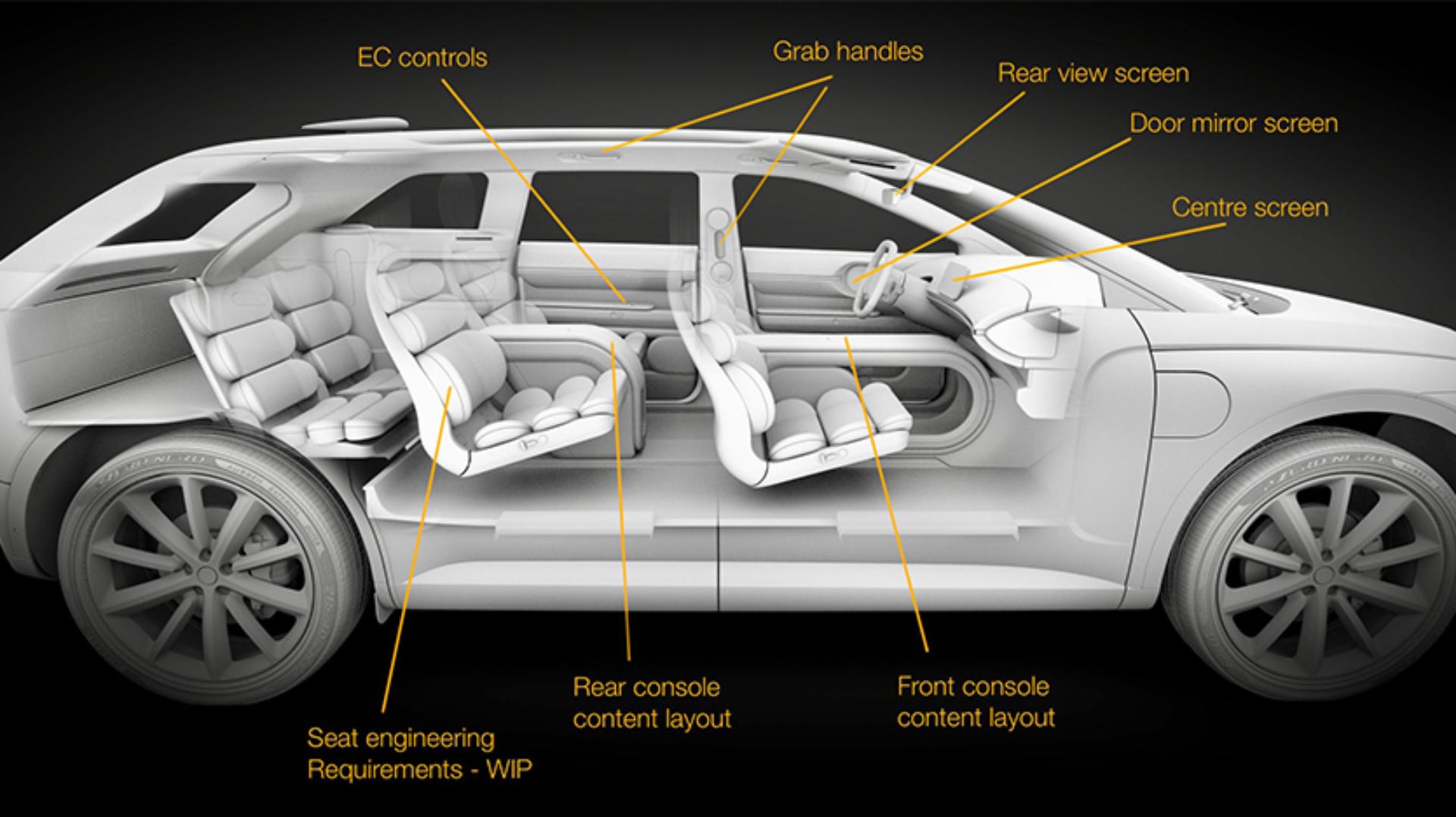

Eames' style

The final design of the seats. Highly comfortable, they were my homage to Eames' iconic padded chair. It was more complicated than we had anticipated to reach this design. Safety laws for car seats meant we had to be even more creative in adhering to regulations without the design being the ugly norm you see in most cars today.

-

Car

We went to great lengths to keep the car under wraps. We only brought the car out into a compound with screens to shield it from view. What you see here is actually a clay model.

-

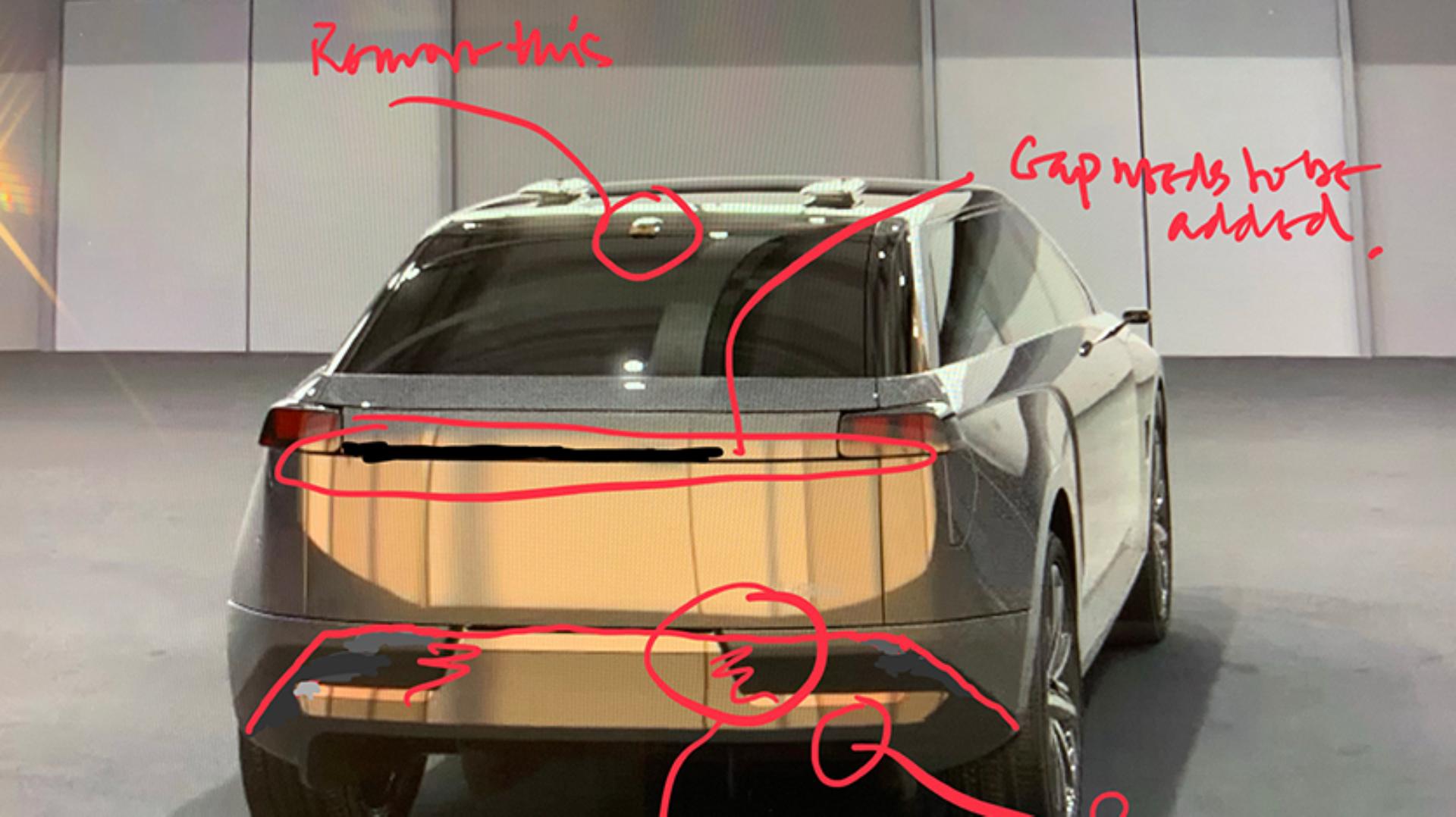

Notes

My notes on the rear view of the car. If I can't feedback to our engineers or work on a project in person, I still like to handwrite my notes as I used to when I first started out.

-

Cross-section

Seating up to seven people, the car was designed to be spacious and comfortable. This was possible because of the spacing of the wheels.

-

Steering wheel

The car's steering wheel held all the controls, leaving the centre console clutter-free. The design removed the need to fumble around with switches on the dashboard.

-

Hullavington

One of the hangars at Hullavington airfield under construction before WWII. It was important to me to bring them back to life rather than simply knock them down and begin again when we bought the property.

-

Hullavington

The interior of Hangar 86 before we moved in.

-

Refining

Always hands on with the car!

-

Seating

The seats were designed to have horizontal pads for lumbar support and good ventilation and better contouring to the body.

-

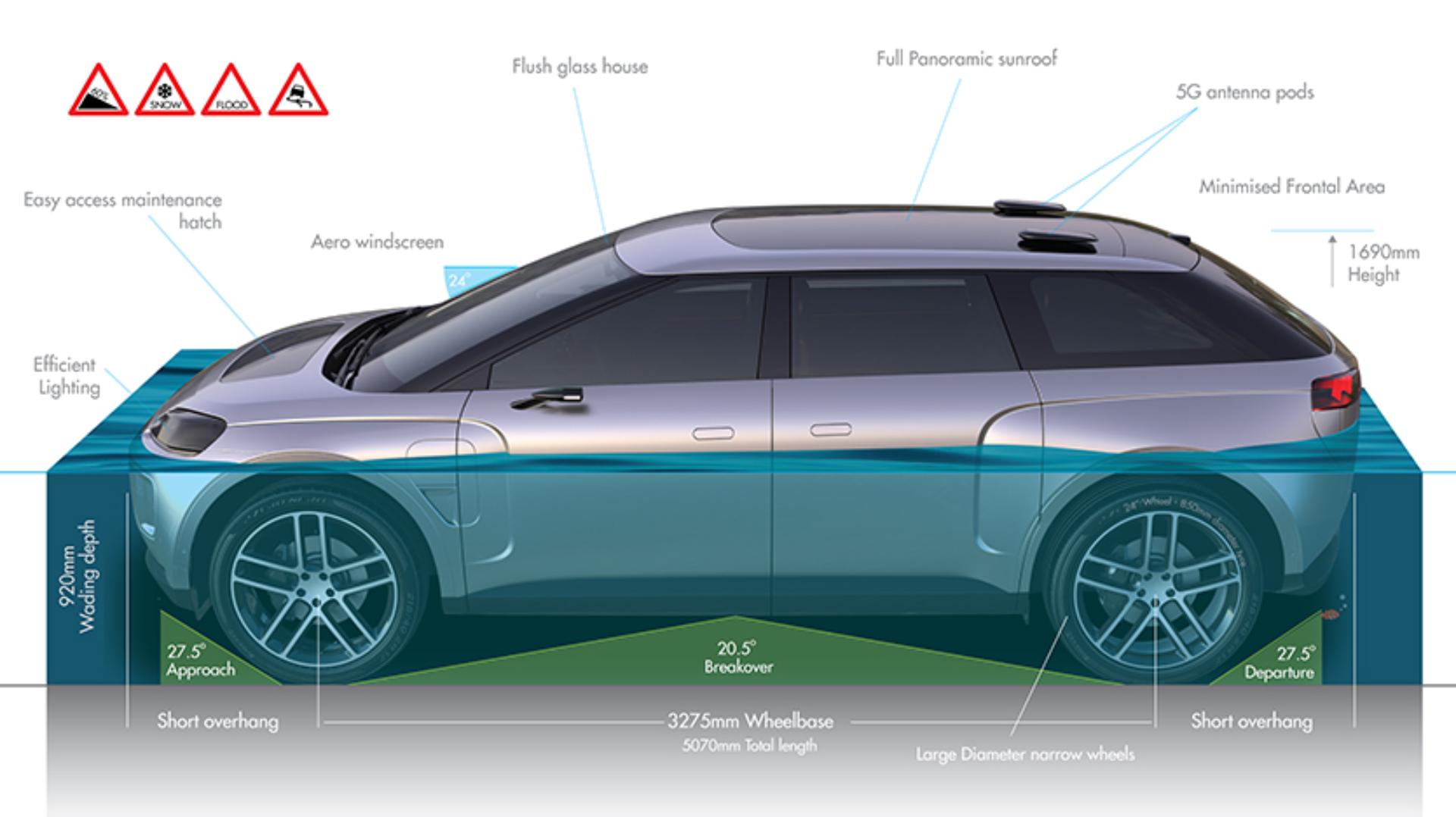

Capability

The car was designed to perform in all terrains – including the ability to wade through flash floods of up to 920mm deep. It had four wheel drive and four wheel steering.

-

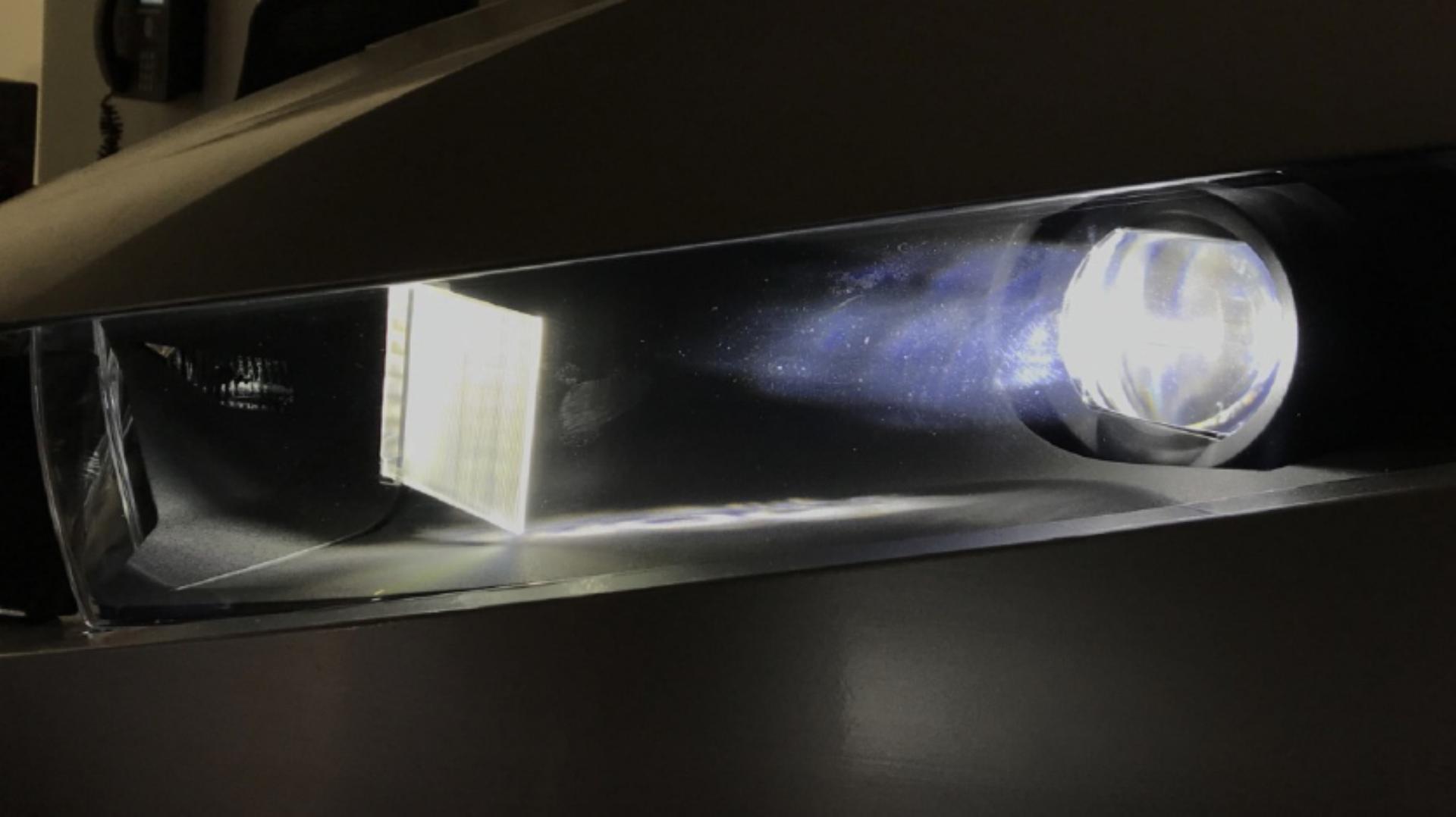

Headlights

The head lamps were projectors and we used live edge acrylic for the indicators which gives a much more intense strip of light.

-

Battery

The battery tray for the car on a trolley. Over 8,500 battery cells gave a 600 mile range.

-

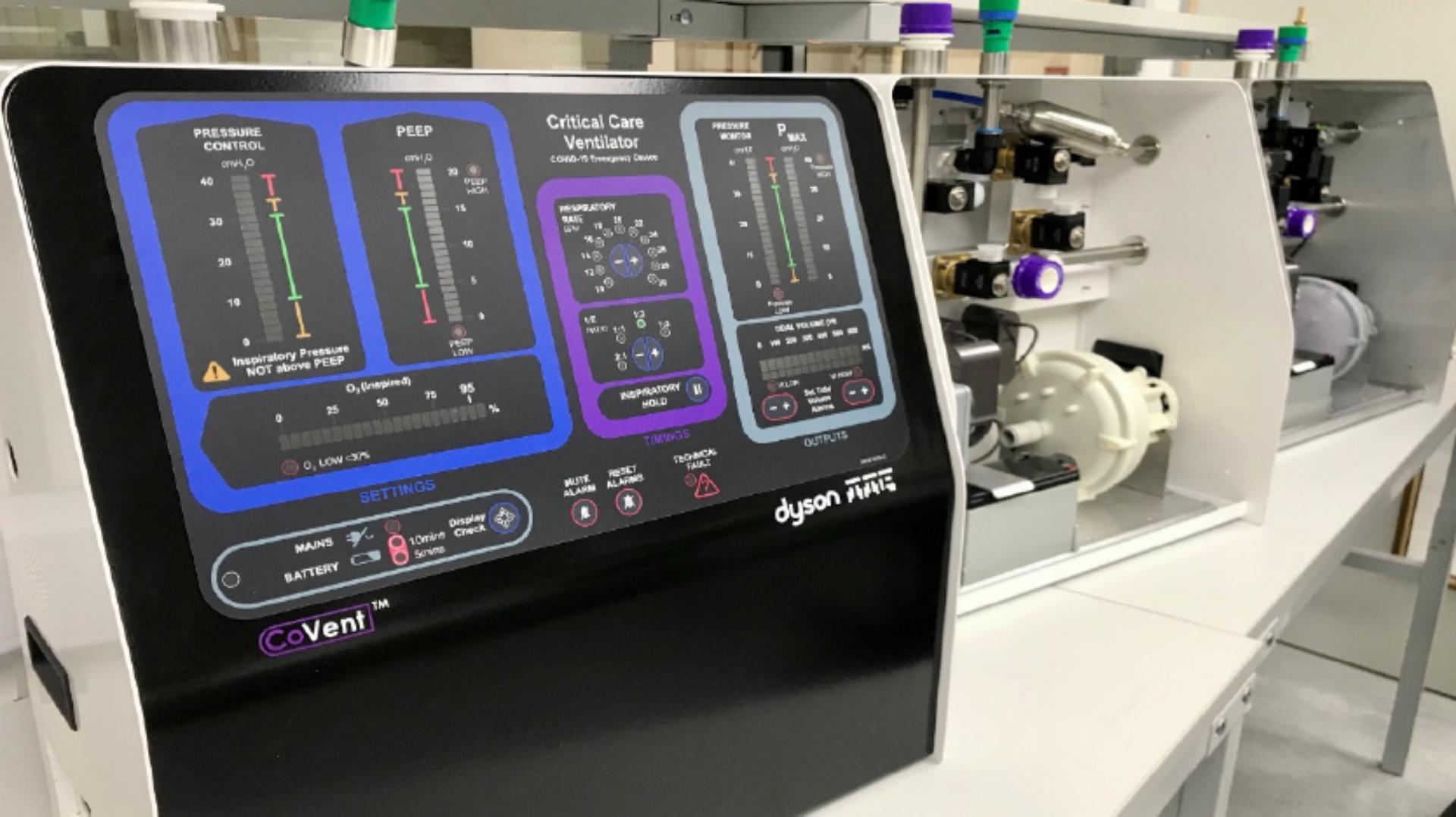

Ventilator

In March 2020, as the COVID-19 pandemic struck, Dyson engineers stopped everything to design a ventilator to help save lives. They did this in just 30 days with Dyson absorbing the £20m it cost to achieve. I am proud to work alongside such people.

-